Of Mines, Mounds and Materials

Architecture and the Anthropocene- Sympoisum

One of the largest open mine pits in the world, the Bingham canyon copper mine in Utah, stretches 2.5 mile wide, half a mile deep and extracts 2 m tons of copper. Just one state away is the Puente hills landfill, the largest dump in America, heaving around 12,000 tons of waste from the LA county’s inhabitants. Each country and almost every state across the globe has its own Bingham mine and Puente landfill. With each passing day, these quarries get dug a little deeper and the mountain of garbage grows a little higher. There develops a seemingly obvious, directly proportional relation between the origin(mines) and destiny(mounds) of a product (fig 1). And this relation is predominantly a volumetric one. Although the minerals, waste and materials are widely different in their nature of use, their movement can be observed with the common measure of quantity. The extraction of minerals from the mines is a subtractive process. These minerals are altered and used in various products which at the end of its use cycle gets accumulated in the landfills, rendering it to be an additive process. Based on this observation, the argument of reversing the volumetric flow from mounds to materials arises, where waste extraction from mounds acts as a subtractive process and the building construction using these materials as an additive process (fig 2). At present, the possibilities of using segregated waste as a raw material for building construction material are abundant. Construction of a building is intrinsically an additive process. One of the emerging construction technology of additive manufacturing finds its place in this argument in the final step of converting waste into construction materials. “As mines become increasingly empty, our buildings become mines themselves”.

With each passing day, the quarries get dug a little deeper and the mountain of garbage grows a little higher. There develops a seemingly obvious, directly proportional volumetric relation between the origin (extraction) and destiny (disposal) of a product.

Image 1

Waste through centuries

The accumulation of waste began with the growth of early human civilisations. Mayan Indians in particular, had a system where all the waste would be collected in heaps outside the settlement. These heaps of waste would be mixed with the soil, giving rise to huge mounds in their landscapes overtime. The Roman civilisation had a very sophisticated waste management system integrated into the city’s infrastructure. During the middle ages (14th century), some European countries faced extensive outbreak of plague leading to instances where entire cities succumbed to death due to unsanitary conditions. Another huge wave of waste accumulation was witnessed during the world wars (20th century). Streets of Germany were filled will rubble and other war debris. This accumulated debris eventually ended up in landfills and building foundations. Parts of San Francisco like the marina and downtown area were built on landfills and abandoned ship debris. Thus cultural forces of the human species has given rise to the vertical accumulation of manufactured ground. The city thus simultaneously becomes a container of buildings and mines. In recent years, the excessive use of plastic has led to its accumulation in natural systems. The term plastiglomerates and plasticrusts have been coined and witnessed in our (manufactured) nature which stand as potential markers of the Anthropocene (Image 1). The image shows various plastiglomerates - plastic embedded in natural rocks. And then poses a possibility of a manufactured brick, where we extract the plastic from our natural systems repurpose and contain it within our built environments.

In the light of the Anthropocene, the gray areas of planetary cleanliness takes new color through concepts of clean energy and clean materials. This opens up a platform for the representation of contemporary architecture of repurposed waste as circular, resilient and more importantly, desirable.

Image 2

Waste and society : The perception of waste

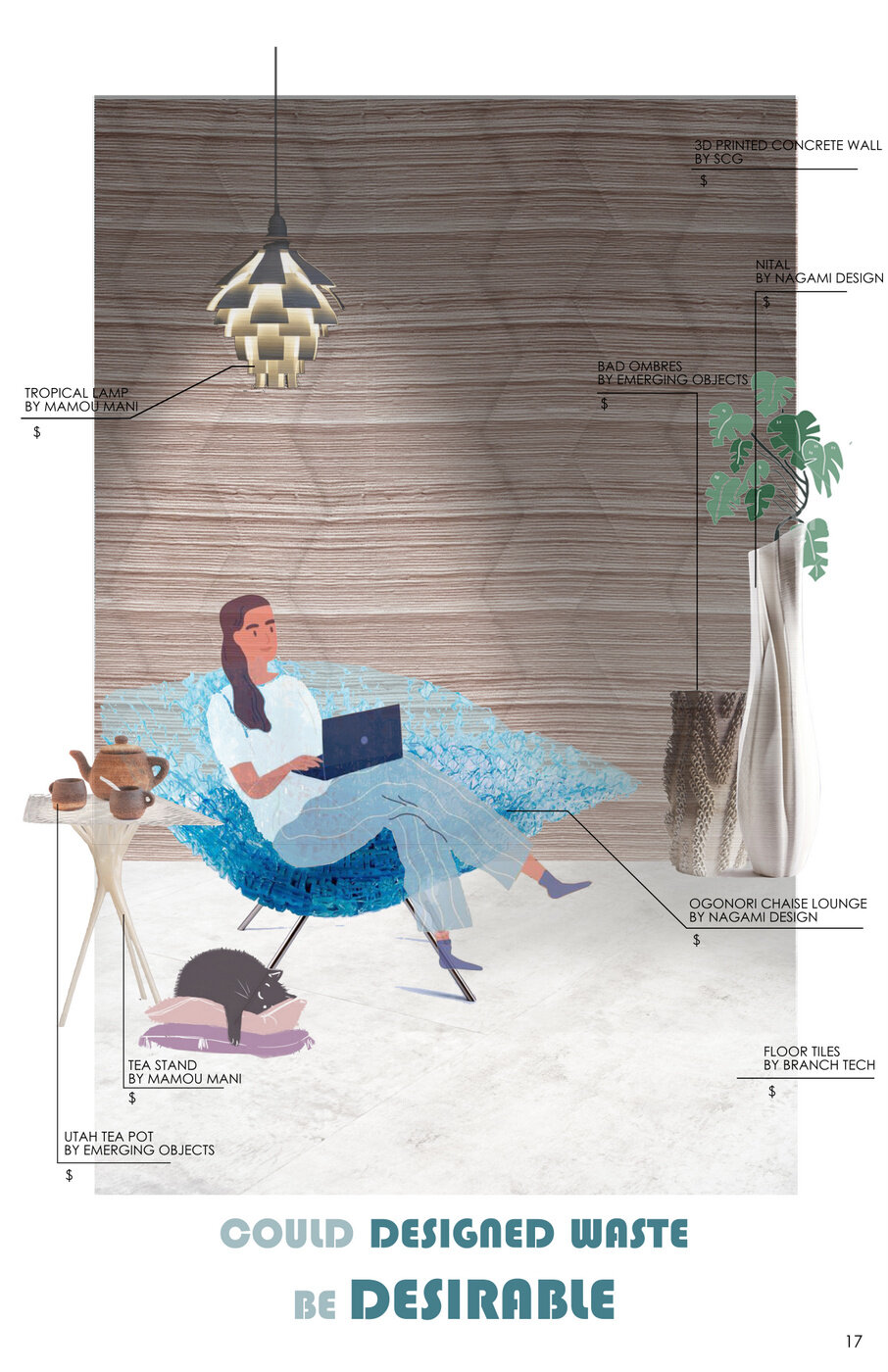

Waste is neither a natural resource nor a synthesised material. It is a byproduct of our lifestyle. This problem of failing to identify waste as a useful resource has led to its unprecedented accumulation in the dump yards. The wave of modern architecture has washed the buildings off all its impurities, leaving behind clean lines, white walls and sterilised design representations. In the light of the recent Anthropocene, the gray areas of planetary cleanliness takes new color through concepts of clean energy and clean materials. This opens up a platform for the representation of contemporary architecture of repurposed waste as circular, resilient and more importantly, desirable. Detaching the association of waste with uselessness, we open up new possibilities for designed waste. Image 2 is a take on the consumerist nature of everyday products. Glossy magazines showing designer products from furniture to light fixtures; mock up of the ideal combination of products for a themed living room or kitchen. The image, looks like a typical page from a magazine, with listed products and price. Examining the details, one can observe that each of the product listed is a 3D printed object. From the furniture and flower pot to the concrete wall itself, all the products have been designed by various 3D printing design practices across the globe, juxtaposed to develop a living area. Could this image trigger a sense of desire to own these products in a consumer? Can this provocation be further extended to a neo lifestyle where repurposed waste products are almost banal?

Waste and additive manufacturing

Although additive manufacturing of products is gaining momentum, the development of this technology for construction is still at a nascent stage. Significant research is being conducted both by academia and private practices to design efficient machines, toolpaths for print and construction method. Emerging objects, build your city, Nagami design, Norman foster foundation, Mamou Mani, Branch tech and AI build are some of the design practices in this field producing significant working prototypes. This essay investigates two design practices that are specifically attempting to use recycled materials for additive manufacturing. Norman foster foundation and Nagami design collaborated during the Robotics Atelier 2019, to design building systems from recycled plastic. During the week long exploration, research candidates from across the globe got together to design building facade systems. Different types of recycled plastic, such as PETG, ABS, Mezcla polvo and plastic pellets were used. One of the main challenges of printing recycled plastic is the consistency of the output. Inefficient segregation methods, impurities in the raw material and prolonged exposure to moisture at room temperature contributed towards inconsistent plastic extrusion from the nozzle, rendering it unfit for printing. Plastic is a porous material and to overcome the problem of moisture, the raw plastic was warmed in an oven before being fed into the printer. After a few experiments, PETG and fresh plastic pellets were determined to be the most efficient plastic raw material for 3D printing the prototypes. The use of new plastic pellets versus a completely recycled plastic, raises the question of the purity of waste being used. And further research would be needed to achieve a net zero-waste printing system. This line of thought opens up further possibilities of reusing the plastic components at the end of the building’s life cycle, by simply melting it and feeding it back to the printer to print different components. Although theoretically possible, there has been no evidence suggesting this practice. Further, the raw plastic needs to be heated before it gets extruded out of the nozzle. This could potentially pose a risk of generation of toxic fumes. By far, only in the PETG type plastic, these fumes are produced in almost negligible quantities.

Image 3

Like most new technologies, several iterations would be necessary before successfully printing a net zero waste building system from recycled materials. But once established, this system could significantly reduce the demand on mines for natural resources. And aid in restoring the volumetric balance between the mines, mounds and materials. As a summary to this thought, the final image (image 3) shows the additive and subtractive relationship between mines, mounds and materials, and explores the role of additive manufacturing as an equaliser in this system.

Bibliography

1.Data from article titled- Bingham Canyon, Copper Mine, Utah, USA https://www.mining-technology.com/projects/bingham/

2. Thelma Gutierrez and George Webster, “Trash city: Inside America’s largest landfill site”, CNN, 2012

3. Ruby, Ilka and Andreas ‘Mine the city’, in Re-inventing construction, Ruby press, Berlin, Germany (2010). “As mines become increasingly empty, our buildings become mines themselves”.

4. City Ground by Stephen Graham, Nov 2016. For the terrestrial material of our rapidly urbanizing species is increasingly anything but “natural” : it is the vertical accumulation of manufactured ground.

5. Article titled Plastiglomerates by Kirsty Robertson, on e-flux. Dec 2016.

6. Norman foster foundations, Robotics Atelier 2019. https://www.normanfosterfoundation.org/educational/norman-foster-foundation-workshop-2019-robotics/

7. Building from Waste- Recovered materials in Architecture and Construction by Hebel et. al. Published on : Sept 2014