Light industries are established in Darfur, Sudan, primarily to provide employment to the people of the region, helping them overcome the effects of war displacement. The project begins by identifying the cottage industries along with the natural resources available locally which can be used as an input for the industries. From our studies on circular economy, we look at ways to complete the input and output flow of materials and aim for zero waste.

Some of the common resources that are abundant around Darfur are sugarcane, cotton, palm, leather and livestock. Utilizing these resources, small industries like basket weaving, pottery, tannery, soap manufacturing and food processing are proposed for the region. The establishment of these industries will be incremental - 5, 10 and 20 year plans are proposed. In the first phase (5 year plan), cottage industries which do not use heavy machinery, and do not require skilled laborers are established. In the next phase, small scale industries that use some electricity and machines are proposed. In the third phase, the by-products of the industries give back energy to the grid and also exports some of the goods and achieves maximum employment but in a circular and sustainable way. Further, the location of these industries are marked in coordination with the site planning, water management and energy groups. Proximity to natural resources and roadways are maintained.

For tannery, a combination of 3D printing and traditional techniques are used. The steps of soaking, de liming, dyeing are incorporated within the 3D printed pits. Sap from Acacia trees are used for dyeing. The leftover organic waste such as fur, fat and sap is transported to bio digesters through a network of pipes. Thus regulating the odor for better working conditions. The leather products such as shoes(markoobh), bags and embellishments produced here are used both locally and exported.

Basket weaving is a local craft. Palm leaves, which are available abundantly are used to make a variety of products such as baskets, mats, wall partitions and roofs. This activity of weaving is also a good community builder and helps women generate a stable income.

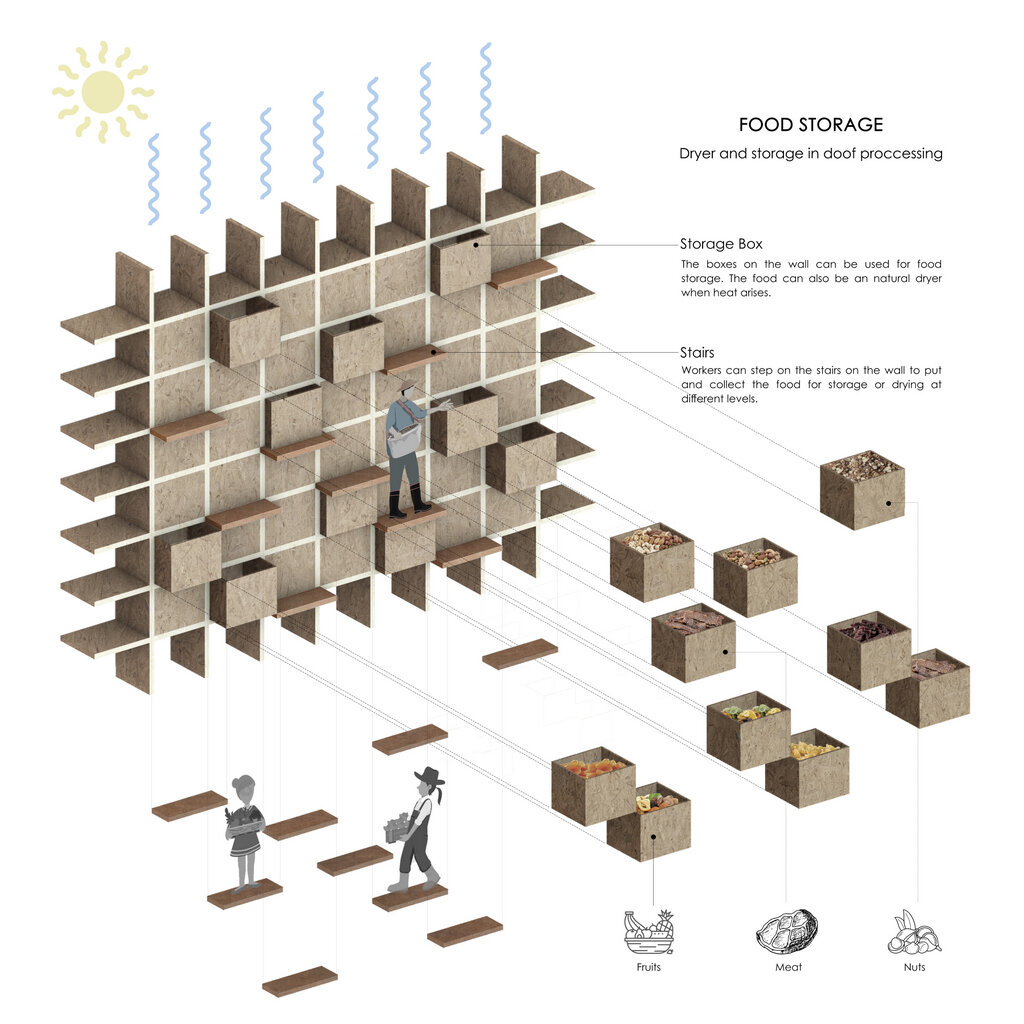

For food storage and food processing, 3D printed elements are considered. On account of the high thermal mass of the clay printed storage boxes, they act as natural food dryers. In the design of a food processing building, perforated clay tiles are used. With the combination of rain water and dry air passing through these tiles, the temperature inside the building remains cool and is ideal for food storage.